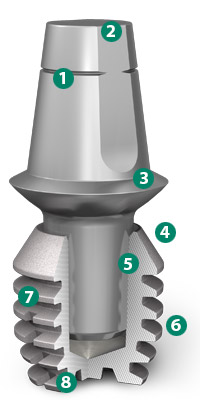

The Bicon Design

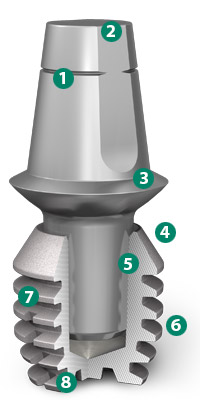

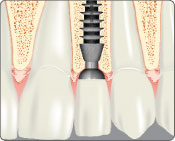

The Bicon System was designed not as a research project to study osseointegration, but rather as a means to restore dentition. Bicon’s unique 1.5° locking taper implant to abutment connection follows sound bioengineering principles and provides for 360° of universal abutment positioning. Bicon’s implant to abutment connection also has been definitively proven to be bacterially sealed. The implant’s elegant plateaued design provides for cortical-like bone with central vascular systems around the implant. This cortical-like bone not only grows faster, but also provides for functionally different capabilities than the appositional bone around non-plateaued implants. The implant’s sloping shoulder provides sufficient space for the interproximal papillae, which are crucial for gingivally aesthetic restorations.

Since its introduction in 1985, the Bicon design has benefited from a sensible biological width, which is only now—over 20 years later—being promoted as platform switching. For these reasons, Bicon clinicians and their patients do not experience the frustrations and limitations inherent in other implant designs.

1: RESTORATIVE FLEXIBILITY

Since 1985 » Bicon offers a complete selection of abutments: temporary, healing, stealth shouldered, non-shouldered, fixed-detachable, Brevis™ overdenture, and Locator® overdenture — providing for exceptional restorative flexibility and platform switching. All Bicon abutments are completely interchangeable, and all benefit from the unique 360° of universal positioning provided by Bicon’s locking taper connection. Once clinicians appreciate what 360° of abutment positioning can do for their clinical practice, implant dentistry will never again be the same for them.

« Previous | Next »

2: EXTRA-ORAL CEMENTATION & THE IAC™

Since 1985 » With the elimination of screws, Bicon’s restorative procedures are conventional, requiring only standard impression techniques and allowing for intra-oral or extra-oral cementation techniques. Because of Bicon’s 360° of universal abutment positioning, Bicon introduced the revolutionary Integrated Abutment Crown™ (IAC), a screwless and fully retrievable restoration. The IAC affords the dentist a guaranteed aesthetic subgingival crown margin for every restoration, with no extra effort or expense for the dentist or technician.

« Previous | Next »

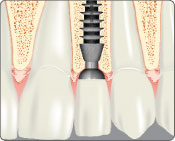

3: NARROW® IMPLANTS

Since 1985 » Bicon NARROW® Implants facilitate the restoration of missing maxillary lateral incisors as well as individual mandibular incisors. The sloping shoulder of the Bicon implant enhances crestal bone preservation while providing space for the interdental papillae — offering the opportunity for natural-looking gingival aesthetics.

« Previous | Next »

4: SLOPING SHOULDER

Since 1985 » Bicon’s sloping shoulder affords more flexibility at the time of implant placement and provides for impressive bone maintenance. It also provides more room for bone over the implant, which provides support for the interdental papillae, enabling aesthetic gingival contours to be easily and consistently achieved.

« Previous | Next »

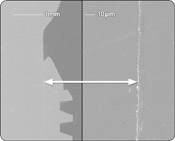

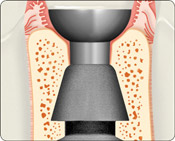

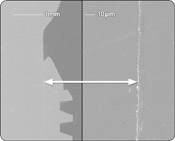

5: 1.5° LOCKING TAPER

Since 1985 » Bicon’s 1.5 degree locking taper connection provides a proven bacterial seal at the implant to abutment interface, with a microgap of less than 0.5 microns. Bicon’s bacterial seal avoids the microbial leakage issues that can result in inflammation of the soft tissue around an implant, which could lead to not only bone loss around the implant but also to the loss of the implant itself.

Image courtesy of Ziedonis Skobe, PhD, Forsyth Institute and Harvard University, Boston, MA and Thomas G.H. Diekwisch, DDS, PhD, UIC College of Dentistry, Chicago, IL

« Previous | Next »

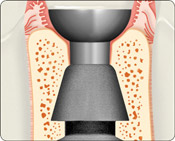

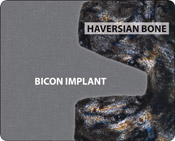

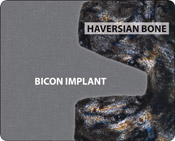

6: PLATEAU DESIGN

Since 1985 » The plateau or fin design offers at least 30% more surface area than a screw implant of the same dimensions and allows for the callus formation of mature haversian bone between the fins of the implant. This cortical-like bone forms at a faster rate of 10-50 microns per day in comparison to the appositional bone around non-plateaued implants, which forms at a slower rate of 1-3 microns per day.

Image courtesy of Paulo G. Coelho, Ph.D., New York University

« Previous | Next »

7: SHORT® IMPLANTS

Since 1985 » Bicon SHORT® Implants maximize implant placement possibilities and minimize the need for grafting procedures. With Bicon, longer implant lengths are not necessarily better. For many clinical situations, shorter implants offer a better solution.

« Previous | Next »

8: LOW-SPEED DRILLING

Since 1985 » Low-speed drilling at 50 RPM without irrigation allows a clinician to harvest the patient’s own bone with titanium reamers for autogenous grafting. Slow drilling is forgiving and is unique to Bicon. Additionally, it greatly extends the longevity of the titanium reamers, thus reducing a clinician’s costs.

« Previous | Next »